Bad blade selection can give you tough times while cuttting. Picking the right jigsaw blade is super important for getting precise and quality cuts in your project. If you’re wondering which jigsaw blade to use, you’re on the right track!

Your blade selection can detemine the outcomes. This guide helps you choose the right blade for any task with important tips. We cover everything, from blade mounts to different blade materials.

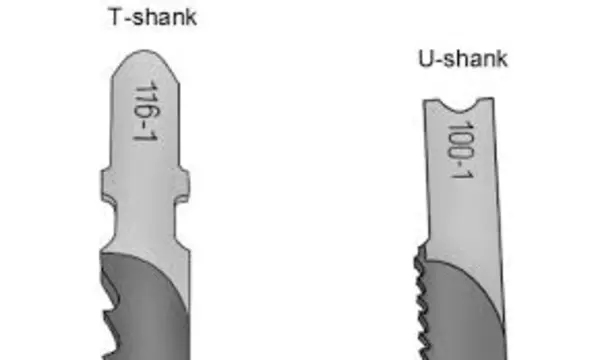

Which Jigsaw Blade To Use T or U: Shank Selection?

When choosing a blade for your jigsaw, the first thing to consider is how it attaches. whether your jigsaw requires a T-shank or a U-shank blade. Older models and some budget-friendly options still utilize the U-shank, secured by a setscrew.

So, most modern jigsaws feature the user-friendly T-shaped tangs, allowing for quick and tool-free changes. Yet, most modern jigsaws use T-shaped tangs that slide in and lock in place without the need for tools. Consider your jigsaw’s compatibility and whether it accepts both T and U types.

Which Metal Composition of Jigsaw Blade is Best?

1. High-Carbon Steel (HCS) Blades:

Best for: High carbon steel blades work really well when cutting wood, MDF, or plastic. They’re super hard and stay sharp, making them great for detailed jobs like cutting wood in woodworking.

They’re tough enough to give clean cuts in MDF, leaving a smooth finish. When it comes to cutting plastic, these blades stay sharp and let you shape it precisely. So, high carbon steel blades are like all-around champs, making them a solid choice for cutting through different materials easily.

Characteristics: High Carbon Steel (HCS) blades are popular for being flexible, making them great for detailed scroll cutting and projects that need precision. They strike a good balance between being flexible and affordable, making them a smart choice for various tasks.

Common Uses: High Carbon Steel (HCS) blades are frequently employed in woodworking, crafting, and projects involving softer materials. They are versatile and well-suited for tasks that require precision in these areas.

2. High-Speed Steel (HSS) Blades:

Best for: High Carbon Steel (HCS) blades shine when cutting through nonferrous metals and acrylics, including aluminum and Polymethyl Methacrylate (PMMA). These blades are designed for precision, offering accurate cuts and shaping capabilities in these specific materials. The flexibility of HCS blades further enhances their suitability for intricate tasks on nonferrous metals and acrylics, providing a reliable choice for diverse cutting applications.

Characteristics: Blades crafted from High-Speed Steel (HSS)are renowned for their durability in cutting tough materials, boasting an extended lifespan compared to High Carbon Steel (HCS) blades. However, the increased rigidity of HSS blades makes them more susceptible to breakage, particularly in challenging situations.

This key difference highlights that while HCS blades offer greater flexibility, HSS blades excel in longevity and resilience against demanding cutting tasks.

Common Uses: High-Speed Steel (HSS) blades find frequent application in metalworking, particularly when cutting nonferrous metals, and tasks demanding a more robust blade. Their durability and resilience make them well-suited for challenging cutting operations in these contexts.

3. Bimetal (BIM) Blades:

Optimal for : Bimetal (BIM) blades are awesome for cutting through various stuff like wood, metal, and laminates. They’re super versatile, making them a top pick for many different cutting jobs with these materials. If you need a reliable blade for diverse projects, Bimetal blades are a solid choice.

Characteristics: Bimetal blades are a great choice because they blend the flexibility of HCS with the durability of HSS. This mix makes them less likely to break, and they work well for many different jobs. The combination of features in Bimetal blades means they’re good for a wide range of tasks, giving you a versatile option for your cutting needs.

Common Uses: Bimetal blades are commonly used for a variety of cutting tasks that involve wood, metal, and laminates. They are especially handy in situations where a balance of flexibility and durability is crucial. This versatility makes them a reliable choice for a wide range of cutting applications.

4. Tungsten Carbide Blades:

Best for: Tough Jobs, Embedded Nails, Metal

Characteristics: Tungsten Carbide blades are specifically designed for challenging tasks, such as cutting through embedded nails or metal. They provide exceptional durability and resilience, making them suitable for heavy-duty applications. Blades without teeth but with tungsten carbide grit are great for cutting tough stuff like glass, concrete board, brick, and tile.

Common use: The blade is used for demolition, cutting tough materials, and durable tasks.

To pick the right jigsaw blade for your project, understand the characteristics and uses of each type. This will ensure efficient and precise cutting.

The Truth About Teeth (TPI):

The number of teeth per inch (TPI) affects how fast and well a jigsaw blade cuts. Blades with fewer teeth (10-24) cut faster but leave a rougher edge. Blades with more teeth per inch (TPI), like above 24, give smoother cuts but take a bit longer.

They’re perfect for careful, detailed work where a super smooth finish is important. It’s crucial to find the right balance between cutting fast and achieving a good finish. Knowing about TPI helps you pick the right blade for exactly what you’re working on.

Specialty Blades for Specific Materials:

Exploring specialty blades expands the versatility of your jigsaw. Knife-edge blades are made to cut soft materials such as leather, cork, and foam insulation.

If your jigsaw can use flush-cut blades, it allows you to cut up to the front edge of the saw’s footplate. This helps make smooth and accurate cuts. Diamond blades are made for cutting tough materials like glass, granite, and slate.

Lastly, reverse-tooth blades cut on the downstroke. They give a smooth top surface to veneered plywood and laminates. This surface is free from splinters. By understanding how to use these special blades, you can tackle a variety of projects.

Conclusion:

Mastering the art of jigsaw blade selection involves a comprehensive understanding of how blades mount, the metal compositions available, the impact of teeth per inch, and the versatility offered by specialty blades.

Armed with this knowledge, you can confidently choose the right blade for any job, ensuring clean, precise cuts with your jigsaw across various materials and project requirements.