Electric chainsaws are a popular choice among homeowners and professionals alike due to their convenience and ease of use. However, like any other power tool, electric chainsaws can experience common issues that can hamper their performance.

In this article, we will discuss common electric chainsaw problems and provide you with practical solutions to fix electric chainsaw common issues.

Few Things To Know:

First Thing First: If you have just bought your chainsaw and it was working fine for few hours and later on started to cause problems then their is a possibility of manufacture defect in the chainsaw in this case if you have time you should immediately return the chainsaw, otherwise if you are facing problems after the return date has ended then go for claiming warranty.

The Lifespan: According to tests carried on chainsaw it is studied that it has average lifespan of 16 months and in many other cases only 11 months. In this case go for buying new chainsaw as the problems after this age are impossible to fix don’t waste your time. You can buy new chainsaw. Following chainsaw are best to buy.

- BLACK+DECKER Electric Chainsaw

- SKIL PWR CORE 20 Brushless

- CRAFTSMAN Electric Chainsaw, 16-Inch, 12-Amp

Common Electric Chainsaw Problems:

1 .Chainsaw Won’t Start:

One of the most frustrating issues with an electric chainsaw is when it refuses to start. Here are a few potential causes and their solutions:

First thing first. Make sure it’s connected to a working power outlet if it’s an electric one with a cord. Check that the cord is not damaged or any pressed twist. If you’re using a cordless chainsaw, make sure the battery has enough charge.

This ensures the chainsaw works well and you can use it without any problems. Always check the power supply to make sure everything is good before you start using the chainsaw.

Inspect the Power Cord: Check if there are any obvious problems like cuts or wires that are coming apart. If you see anything wrong, it’s important to get a new power cord.

Using a damaged cord can be unsafe, so it’s better to replace it with a new one to make sure everything works well and you stay safe while using it. Always make sure the power cord is in good condition before using the tool.

Clean the Air Filter: It’s essential to make sure the air filter is clean. A dirty or clogged air filter can stop the chainsaw from working. Take out the air filter and clean it following the instructions given by the company that made the chainsaw.

This helps air flow properly, making the chainsaw start easily. Regularly cleaning the air filter keeps the chainsaw in good shape and ready to use whenever you need it.

Inspect the Spark Plug: A faulty or dirty spark plug can also hinder the chainsaw from starting. Remove and clean the spark plug or replace it if necessary.

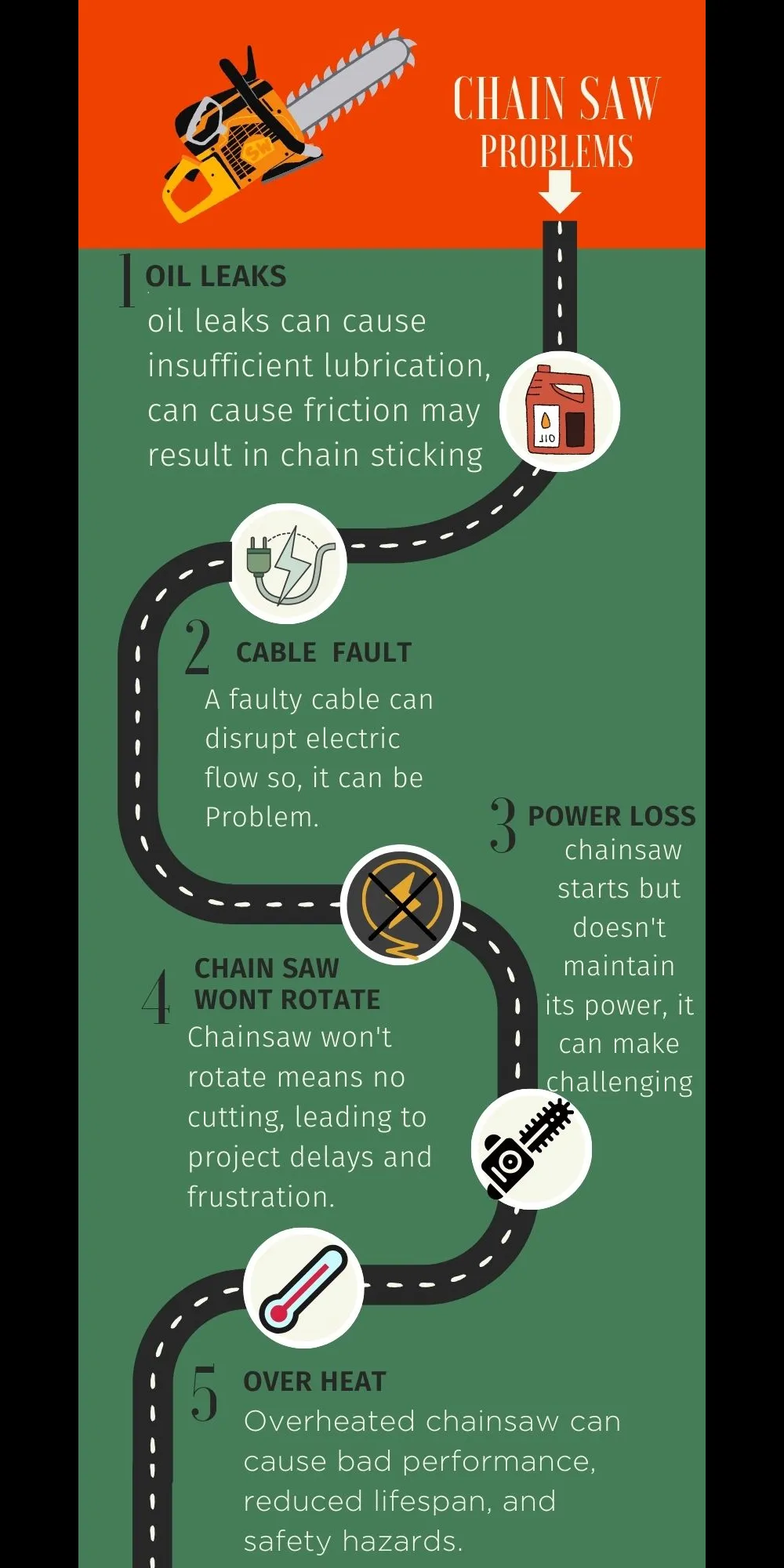

2. Chainsaw Loses Power:

If your electric chainsaw starts but doesn’t maintain its power, it can make cutting tasks challenging. Here’s what you can do to address this issue:

Checking the Chain Tension: Ensure the chainsaw chain is neither too loose nor improperly tensioned, as this can result in power loss. Refer to the manufacturer’s guidelines to adjust the chain tension correctly. A well-tensioned chain contributes to the chainsaw’s optimal performance.

Sharpening the Chain: To maintain power, it’s crucial to keep the chainsaw chain sharp. Dull chains put extra strain on the motor, causing power loss. Use a chainsaw sharpener or seek professional help to sharpen the chain as needed. A sharp chain ensures efficient cutting and prevents unnecessary stress on the chainsaw’s motor.

Cleaning the Chain and Bar: Accumulated debris and residue on the chain and bar can hinder the chainsaw’s cutting ability, leading to power loss. Thoroughly clean the chain and bar using a brush and lubricant to remove any buildup. This regular maintenance enhances the chainsaw’s cutting efficiency.

Inspecting the Motor Brushes:

Worn-out motor brushes can contribute to power loss in the chainsaw. Check the brushes for signs of damage or wear, and replace them if necessary. Regular inspection and replacement of motor brushes ensure the motor operates effectively, maintaining consistent power output.

3. Chainsaw Chain Won’t Rotate:

When the chainsaw’s chain refuses to rotate, it renders the tool useless. Here’s how you can troubleshoot this problem:

Checking the Chain Brake: Before using the chainsaw, make sure the chain brake is not engaged. If the brake is activated, the chain won’t rotate. Follow the instructions provided by the manufacturer to disengage the chain brake properly. This ensures that the chain can move freely during operation.

Inspecting the Sprocket: Examine the sprocket, the wheel-like component where the chain wraps around. Look for any signs of damage or debris buildup. Cleaning the sprocket and applying lubrication with chainsaw oil helps maintain smooth rotation and prevents interruptions in the chain movement.

Examining the Chain Tensioner: A properly functioning chain tensioner is crucial for the chain’s rotation. Check the tensioner to ensure it is correctly adjusted. If the tensioner is faulty, it may hinder the chain’s movement. Refer to the manufacturer’s instructions for proper adjustment to allow the chain to rotate freely.

Checking the Chain Drive Gear: The chain drive gear is responsible for transferring power from the motor to the chain. Inspect it for any damage or signs of wear. If the gear is compromised, it might be necessary to replace it. Follow the manufacturer’s guidelines for the correct replacement procedure, ensuring the chain drive gear is in good condition for smooth rotation.

4. Chainsaw Chain Gets Stuck:

Dealing with a stuck chainsaw chain can be frustrating, but with a few troubleshooting steps, you can resolve the issue:

Stopping the Chainsaw: If the chain gets stuck, immediately switch off the chainsaw and unplug it from the power source to prevent accidents. This ensures safety and allows for a careful assessment of the situation without the risk of injury.

Untangling the Chain: Inspect the chain for any entangled material, such as wood chips or branches. Use a screwdriver or a pair of pliers to gently and carefully untangle the chain. Taking this step ensures that the chain is free from obstruction, allowing it to move smoothly during operation.

Checking the Chain Brake: Before restarting the chainsaw, make sure the chain brake is fully disengaged. If it’s engaged, release it following the manufacturer’s instructions. A properly disengaged chain brake is essential for the unhindered movement of the chain.

Lubricating the Chain: To prevent the chain from getting stuck due to insufficient lubrication, apply chainsaw oil to ensure smooth operation. Proper lubrication is vital for the longevity and efficient performance of the chainsaw. Regularly applying chainsaw oil keeps the chain moving freely, reducing the likelihood of it getting stuck during use.

5. Chainsaw Overheats:

An overheating chainsaw can be a safety hazard and can shorten the tool’s lifespan. Follow these steps to prevent or address overheating:

Proper Chain Lubrication: For smooth operation, make sure the chainsaw chain is well-lubricated. Using chainsaw oil keeps the chain moving smoothly, reducing friction that can lead to overheating. Regularly check the oil level and refill it as needed to ensure proper lubrication during use.

Taking Breaks: When using the chainsaw for an extended period, it’s essential to give it regular breaks. Continuous use can lead to overheating. Taking breaks allows the chainsaw to cool down, preventing potential damage from prolonged heat exposure.

Cleaning the Air Vents: Blocked air vents can restrict airflow and contribute to overheating. Keep the chainsaw’s air vents clean using a brush to remove dust and debris. This ensures proper ventilation, allowing the chainsaw to operate efficiently without the risk of overheating.

Inspecting the Cooling Fan: The cooling fan plays a crucial role in dissipating heat generated during operation. Check if the fan is working correctly and ensure it’s free from any debris that might hinder its function. Cleaning the cooling fan contributes to effective heat dissipation, preventing overheating issues during use. Regular maintenance of the cooling system is essential for the chainsaw’s optimal performance.

6. Chainsaw Oil Leaks:

An oil leak in a chainsaw can lead to various problems affecting its performance and safety. Insufficient lubrication due to a leak may result in increased friction, causing premature wear on the chain and guide bar.

This can lead to the chain sticking or jamming during operation, posing safety risks and hindering cutting efficiency. Overheating is another concern, potentially damaging vital components.

Increased wear and tear on the chain, bar, and sprocket are common consequences of oil leaks. Moreover, oil leaks can have environmental repercussions, contaminating soil and water.

Reduced efficiency, longer cutting times, and the need for more frequent maintenance are additional drawbacks. Regular inspection, prompt leak repairs, and adherence to lubrication guidelines are crucial for maintaining optimal chainsaw performance and safety.

Checking Oil Tank Cap: Before starting the chainsaw, make sure the cap on the oil tank is tightly closed. If the cap is not secured properly, oil might leak while you’re using the chainsaw. To prevent this, ensure the cap is tightened correctly before operating the chainsaw. This simple step ensures a secure seal, preventing unnecessary oil leakage during use.

Inspecting Oil Lines: Examine the tubes that carry the oil, known as oil lines. If you notice any cracks or damage to these tubes, it’s crucial to replace them. Damaged oil lines can lead to oil leakage during operation, impacting the chainsaw’s performance.

Replacing these lines helps maintain the proper flow of oil, ensuring everything stays in good condition and preventing leaks that could cause issues. Regularly checking and replacing damaged oil lines contributes to the overall health and effectiveness of the chainsaw.

Cleaning the Oil Tank: Sometimes, if there’s too much sawdust or dirt in the oil tank, it can create problems. Empty the tank and clean it well. After that, fill it up with the right chainsaw oil. This makes sure there are no clogs or leaks.

Replacing the Oil Pump: If the part of the chainsaw that pumps the oil (the oil pump) is not working well, it could be causing the leaks. In this case, think about getting a new oil pump. Follow what the company says in the instructions to change it correctly. This should stop the oil from leaking.

Conclusion:

By understanding and troubleshooting common electric chainsaw problems, you can keep your tool in optimal condition and ensure smooth operation. Remember to follow the manufacturer’s instructions and exercise caution when attempting any repairs.

Regular maintenance, proper lubrication, and periodic cleaning will go a long way in ensuring the longevity and performance of your electric chainsaw.