Mini chainsaws have become essential tool, and specially in winters if you are going outdoor camping various tasks, from cutting branches to DIY projects. But, if your mini chainsaw is not working can be frustrating. This comprehensive guide aims to help you to know why your mini chainsaw not working and address common problems. To ensure your saw operates smoothly

First Things First:

First Thing First: If you have just bought your chainsaw and it was working fine for few hours and later on started to cause problems then their is a possibility of manufacture defect in the chainsaw in this case if you have time you should immediately return the chainsaw, otherwise if you are facing problems after the return date has ended then go for claiming warranty.

The Lifespan: According to tests carried on various mini chainsaw it is studied that it has average lifespan of 13 months and in many other cases only 8 months. In this case go for buying new chainsaw as the problems after this age are impossible to fix don’t waste your time. You can buy new chainsaw. Following chainsaw are best to buy.

- BLACK+DECKER Electric Chainsaw

- SKIL PWR CORE 20 Brushless

- CRAFTSMAN Electric Chainsaw, 16-Inch, 12-Amp

Why Your Mini Chainsaw Not Working?

1. Check the Bar and Chain:

One of the primary reasons for a mini chainsaw not working optimally lies in the bar and chain. Misalignment or deformation of the bar, improper chain tension, or debris accumulation can hinder performance.

To resolve this, start by checking the alignment of the bar and chain, ensuring they are not misshapen. Adjust the chain tension to the manufacturer’s specifications, avoiding over-tightening or looseness. Regularly clean any debris that might have accumulated in these crucial components, as it can impede the chainsaw’s efficiency.

2. Inspect the Lubrication System:

To keep your mini chainsaw working well, it’s important to make sure it has enough oil in the right places. If the oil system isn’t working properly, your chainsaw might not work as it should. Check if anything is blocking the oil hole and if the oil comes out like it’s supposed to.

Cleaning the oil system regularly helps the chain move smoothly. This is crucial because the chain needs enough oil to cut properly every time you use it. So, remember to check and clean the oil part regularly to keep your chainsaw in good shape!

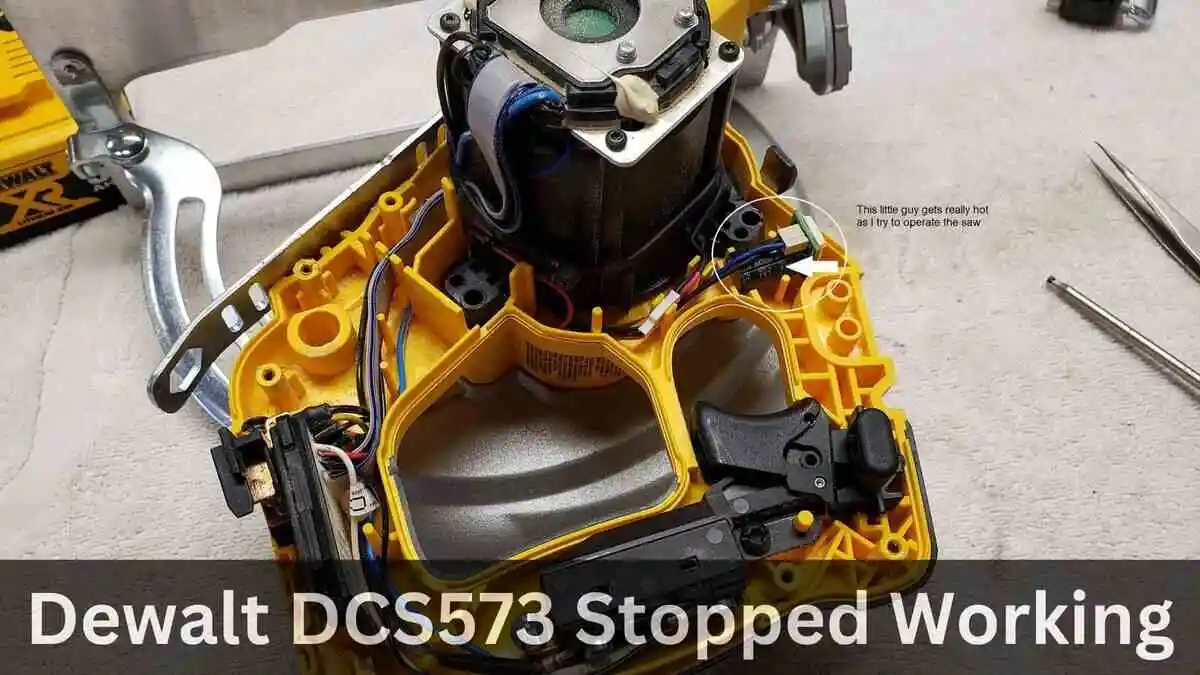

3. Examine the Motor and Internal Switch:

If your mini chainsaw isn’t working right, the problem might be with the motor or switch inside. Check the motor to make sure it’s working like it should. Also, look at the switch connected to the button you press; see if it’s stuck or not working right.

Making sure both these parts work well is super important for your chainsaw to do its job properly. Take a good look at the motor and switch, and if there’s a problem, fixing it will help your chainsaw work better.

4. Battery and Power Supply:

For battery-powered mini chainsaws, a common problem is a battery or power supply not working right. To fix it, first, make sure the battery is charged and working well. If your chainsaw uses a power cord, check the power supply for any issues.

Having enough power is really important for your chainsaw to work its best. Fixing problems with the battery or power supply can often make your chainsaw work better. Remember to regularly check and take care of these parts to keep your chainsaw running well.

5. Chain Maintenance:

The chain in your mini chainsaw is crucial for cutting well. If it’s not in good shape, your chainsaw won’t work properly. Check the chain often for dullness, missing parts, or any signs of damage. Make sure the chain is tight just as the maker suggests.

Regularly sharpen and take care of the chain to keep your chainsaw working effectively. Giving attention to the chain is a key step in ensuring your chainsaw performs well whenever you use it.

6. Commutator Cleaning:

When dealing with electric mini chainsaws, a common hindrance to power delivery is a dirty commutator on the motor. To remedy this issue, it’s essential to clean the commutator using light-grade sandpaper. By doing so, you remove accumulated dirt and ensure smooth electrical contact, promoting efficient power transmission within the motor.

Maintaining cleanliness in the motor’s components is paramount for the overall performance of the chainsaw. Regular attention to the commutator helps prevent potential disruptions, ensuring that the chainsaw operates at its best and prolonging its functional life.

Conclusion:

In conclusion, a mini chainsaw not working can be attributed to various factors. By systematically addressing common issues such as bar and chain alignment, lubrication system problems, motor and switch malfunctions, battery or power supply issues, chain maintenance, and commutator cleanliness, users can troubleshoot and resolve issues efficiently.

Regular maintenance and adherence to manufacturer guidelines will ensure the longevity and optimal performance of your mini chainsaw. If problems persist, consulting professional assistance or referring to the user manual is recommended for further guidance.